Industrial Oils & Coolants

With its core competence in industrial lubrication technology, MOTOREX AG has been a top choice for both small businesses and global corporations for decades. Thanks to close cooperation with machine and tool manufacturers in MOTOREX Synergy Projects, each MOTOREX product is packed with valuable practical expertise. This is reflected in many highly innovative solutions such as Vmax technology, while the “Swiss Made” label guarantees top quality at all times.

Automated Fluid Management

The professional mixing and maintenance system for industry allows water-miscible coolants, cutting oils and grinding oils to be reliably monitored and processes to therefore be safeguarded. Now, as a solution provider, we can provide you with all the support you need. The FLUIDLYNX monitoring system protects your employees, workpieces and production machinery and ensures verifiable and traceable process security. All devices are developed and produced in Switzerland – for our customers worldwide.

Water Miscible Cutting Fluids

MOTOREX SWISSCOOL range of universal high-performance water miscible coolants is suitable for steel, cast iron, aluminum, and exotics.

Cutting Oil

MOTOREX SWISSCOOL range of neat cutting oils gives high performance, long service life, and reduced production costs.

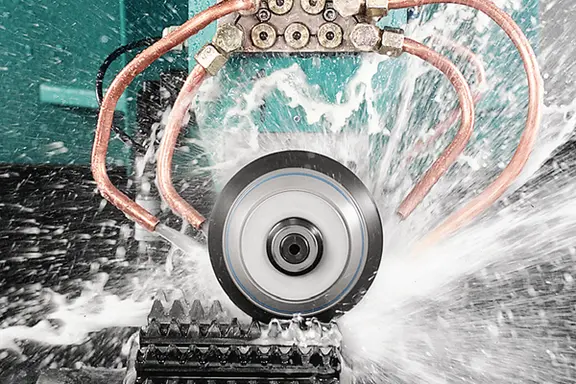

Grinding Fluid

Grinding is a discipline that has to be carried out perfectly. In doing so, components such as the grinding centre, grinding

wheel and grinding fluid must complement each other optimally. Only then can a high-quality, economically convincing performance be achieved. By using products from the MOTOREX SWISSGRIND range, you can benefit from the latest in industrial

lubrication technology for grinding applications.

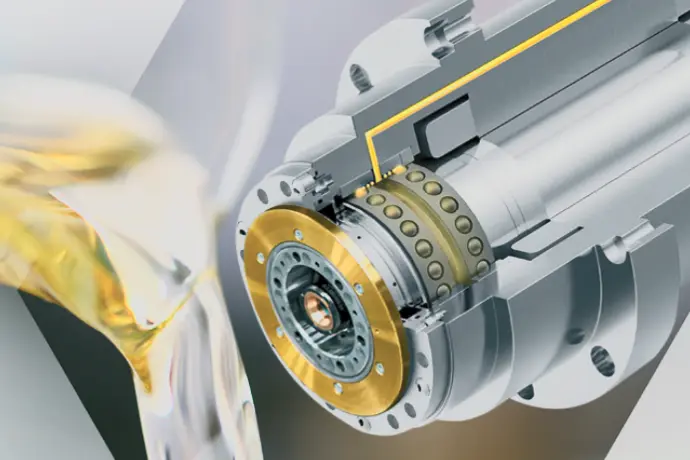

Spindle Line

The intensive research and development work carried out by MOTOREX is refl ected in the comprehensive spindle products on offer. At least 10% of the investment into a machine tool is needed for the spindle itself.

Increasingly powerful spindle systems make up the heart of the latest machining centres. If the spindle rotates at a speed between 10 000 and > 45 000 rpm, the spindle bearing and cooling system are pushed to the limit. MOTOREX works closely with renowned spindle manufacturers around the world. They prescribe the use of various MOTOREX spindle products and in doing so guarantee users the highest level of quality.

Dielectric Oil

MOTOREX ELYSIUM EDM 110 is ideal for roughing and finishing applications thanks to its high dielectric strength. Suitable for use with both copper and graphite electrodes.