Cutting Tools

High performance cutting tools offer a wide range of benefits for various industries and applications. These cutting tools are designed to provide superior performance, precision, and efficiency compared to standard tools. One of the key benefits of using high performance cutting tools is increased productivity. These tools are engineered to cut faster and more accurately, allowing for quicker completion of tasks and projects.

Additionally, high performance cutting tools are known for their durability and longevity. They are made from high-quality materials that can withstand high speeds, heavy loads, and tough materials without wearing out quickly. This results in cost savings for businesses as they do not need to replace the tools as frequently.

Another advantage of using high performance cutting tools is improved surface finish and quality of the cut. These tools are designed to produce clean and precise cuts, reducing the need for additional finishing processes and ensuring a high-quality end product.

Furthermore, high performance cutting tools can also contribute to a safer working environment. Their advanced design and technology help reduce the risk of accidents and injuries, making them a reliable choice for operators.

In conclusion, the benefits of using high performance cutting tools include increased productivity, durability, improved surface finish, and safety. Investing in these tools can lead to enhanced efficiency, cost savings, and overall better results in various cutting applications.

OSG Corporation

Aichi, Japan-based OSG Corporation is the world’s largest manufacturer of round cutting tools. Established in 1938, OSG has a longstanding reputation as a total solution cutting tool provider throughout the manufacturing industry.

OSG holds the No. 1 position in the Japanese cutting tool market as well as a top-ranking position globally.

Main products are: Threading Taps (34% of sales, 30% of global market share), Drills (23% of sales, 5-7% of global market share), End Mills (23% of sales, 12-15% of global market share), Rolling Dies (9% of sales, 25-30% of global market share).

Tungaloy

Headquartered in Japan, Tungaloy provide products to customers all over the world in automobile, construction, aerospace, medical, power generation, infrastructure, and heavy industries.

Since 1929, Tungaloy has been the pioneer in materials research and the development of cemented carbides.

Tungaloy develops cutting-edge technologies by taking advantage of the latest techniques and equipment as well as its close relationship with customers worldwide in all industry sectors.

SIMTEK

SIMTEK stands for high quality carbide precision tools with high performance ability. The standard range of tools includes 10.000 tools for grooving, turning, milling, broaching, thread whirling and polygon milling applications. The standard range starts with small part machining tools for applications in bores as of Ø 0,3 mm and goes up to multirow, highly complex disc milling cutters with a diameter of 200 mm.

Karnasch Professional Tools

Karnasch Professional Tools offers all that matters! We are a family-run business that is actively involved on a worldwide scale, with our head office in Heddesheim in Baden and Görsdorf (Brandenburg), which:

- produces and distributes excellent quality, high performance tools for metal working,

- has been active in the market since 1961 and has accordingly obtained invaluable experience, comprehensive know-how and above average customer orientation,

- guarantees immediate availability of our products at any time thanks to intelligent stock-keeping,

- has sales partners in many regions of the world, and can thus also ensure a continuous and accompanying service for your overseas branches.

- places an emphasis on support and fulfils this claim via, amongst other things, a service hotline.

- cemented our presence throughout Germany with the opening of a branch in Görsdorf (Brandenburg) in 1992.

Our customers predominantly come from the following sectors:

- Tool and mold making,

- Aviation and aerospace,

- The automotive industry,

- Shipbuilding and railway construction,

- Structural engineering, steel construction and bridge building,

- Dental.

Mikron Tool

Mikron Tool emerged from the former tool department of the transfer-machine

manufacturer Mikron SA Agno. The result is decades of experience in the

development and production of cutting tools.

Started as an independent company with 25 employees in 1998, we are now a

globally active tool supplier with our main office in Switzerland (Agno Ticino), a

branch office with sales and manufacturing in Germany (Rottweil), and sales

offices in the USA and China.

250 employees are working daily to satisfy the needs of our customers; a worldwide

sales network with partner companies ensures world-wide customer support

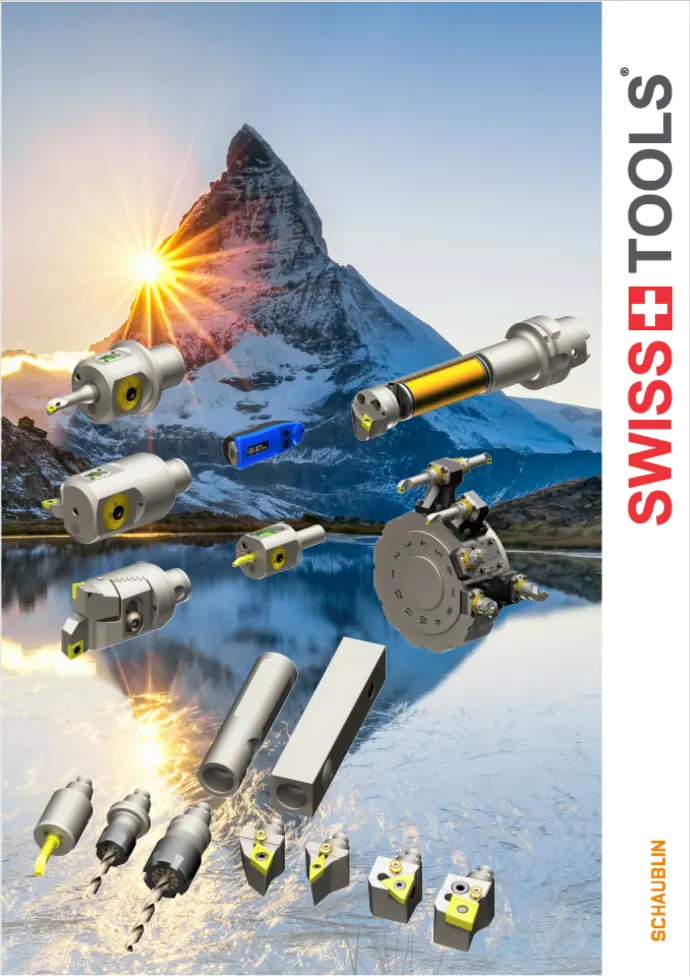

Swiss Tool Systems AG

Swiss Tool Systems AG is a leading Swiss company specializing in the design, development, and manufacturing of high-quality precision modular tools and systems for various industries. With a strong focus on innovation and quality, Swiss Tool Systems AG has established itself as a trusted partner for companies looking for reliable and efficient tooling solutions. The company's products are known for their precision, durability, and performance, making them ideal for a wide range of applications. Swiss Tool Systems AG is committed to providing exceptional customer service and support, ensuring that clients receive the best tools and solutions for their specific needs.