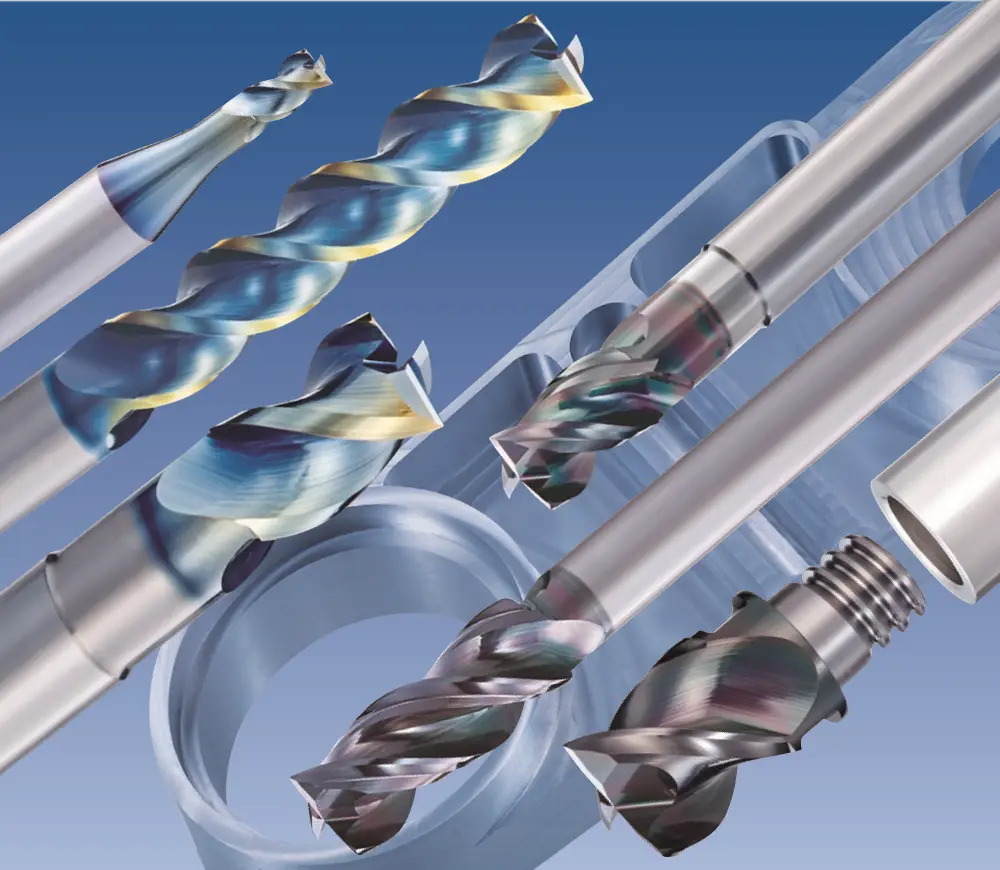

OSG Featured End Mills

In the competitive manufacturing landscape, using high-quality and high-accuracy end mills, such as those from OSG, is crucial for enhancing productivity and reducing scrap. OSG end mills are engineered for durability and precision, resulting in longer tool life and fewer tool changes, which minimizes downtime and maximizes output.

The accuracy of OSG end mills ensures tight tolerances and superior surface finishes, significantly reducing the likelihood of errors and scrap. This efficiency not only saves on material costs but also improves overall operational effectiveness. Additionally, OSG’s design promotes efficient chip removal, preventing tool wear and enhancing cutting performance.

In summary, investing in OSG end mills is a strategic move that leads to increased productivity, lower scrap rates, and a competitive advantage in the manufacturing sector.

AE-VM SERIES

Habitats with a minimum footprint on the planet and a maximum positive impact on the local community.

AE-N SERIES

DLC Coated End Mills for Non-ferrous Materials and copper electrodes. Wide range, very high performance and surface finish!

AE-H SERIES

Carbide End Mills for High Hardness Steels. High performance and accuracy. Extremlly wide range of diameters and lengths.